Cannon Gas Miser Manual

View and Download Flavel MISERMATIC FORM series installation, maintenance & user instructions online. BATTERY IGNITION RADIANT CONVECTOR GAS FIRE. MISERMATIC FORM. Cannon Gas Miser Manual. Have you ever wondered why everything happens the way it does? Who could possibly benefit from all of the suffering and exploitation in this.

. The appliance should not be operated by people (including children) with reduced physical, sensory or mental capacities, by inexperienced individuals or by anyone who is not familiar with the product. These individuals should, at the very least, be supervised by someone who assumes responsibility for their safety or receive preliminary instructions relating to the operation of the appliance. 2000W 3000W 2000W 3000W Timer Control panel Model number & Grill Serial number label Grill pan and Grill pan handle food support fixed/detachable 'Stay Clean' liners Top oven/grill Top Oven door rod shelf Main Oven door Oven light Oven fan Door Switch 'Stay Clean' liners Main oven. ELECTRONIC INIECTION BUTTON. MAIN OVEN TIMER TOP OVEN/GRILL BURNER CONTROLS CONTROL CONTROL. 0 0 0 0 0 0 0 0 0 0 0 0.

0 0 0 0 0 0 0 0 0 0 0 0. 1 3 0 NOTE: The Cookpot symbol disappears. Fixing the Grill Pan Handle The grill pan handle is detachable from the pan to facilitate cleaning and storage.

Cannon Gas Miser

Fix the pan handle securely before use: 1. Fit the handle to the grill pan so that the external ‘hooks’ embrace the edge of the pan (fig. STARTERS FISH MEAT AND POULTRY PUDDINGS. CAKES, PASTRIES AND BISCUITS YEAST MIXTURES MISCELLANEOUS. STARTERS MEAT AND POULTRY VEGETABLES PUDDINGS.

CAKES, PASTRIES AND BISCUITS YEAST MIXTURES MISCELLANEOUS. COOKER FINISH CLEANING METHOD Vitreous Enamel Pain Aluminium Glass Chromium Plating Plastic Stainless Steel. PROBLEM CHECK Hotplate burner: Burner ports Ignitor. PROBLEM CHECK Slight odour or small amount of smoke when grill / oven used first time. Oven cooks too fast or too slow. Cannot set an 'Auto Cook' programme or cannot get the timer to turn the oven on or off at the required times. G30 at 28-30mbar G20 at 20mbar G31 at 37mbar BURNER.

65 mm Min 600 mm Min. Green & Yellow to Earth Brown to Live Blue to 13 Amp 13 Amp 13 Amp 13 Amp Neutral Fuse Cord Clamp. 06/2084.04.

. MISERMATIC BATTERY IGNITION RADIANT CONVECTOR GAS FIRE Installation, Maintenance & User Instructions Hand these instructions to the user Model No’s FORM.EN are for use on Natural Gas (G20) at a supply pressure of 20 mbar in G.B. denotes colour variance. CONTENTS Page Section 1 Appliance Data Conditions of Installation.

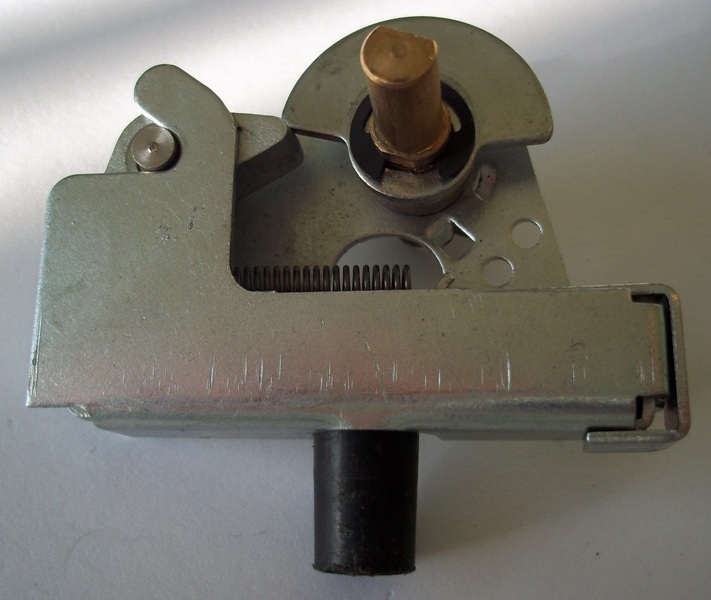

Flue & Chimney Suitability Fireplace/Surround Suitability Shelf Position Side Clearance Closure Plate Flue & Chimney inspection Chimney Catchment space 1.8.1 Brick Built Chimney 1.8.2 Fitting to Pre-Fab. Twin Wall Metal Flueboxes 1.8.3 Fitting to Pre-Cast Flue Installations Hearth Fitting. APPLIANCE DATA Main injector (1 off) Stereomatic Elbow size 76 Pilot Type.

Copreci Single Flame 21100 / 161 Max. Gross Heat Input: 6.9 kW Min. Gross Heat Input: 2.5 kW Cold Pressure: 20.0 +/- 1.0 mbar (8.0 +/- 0.4 in w.g.) Ignition: Battery Ignition, 1.5V Electrode Spark Gap. CONDITIONS OF INSTALLATION In Great Britain:- It is law that all gas appliances are installed only by a registered installer in accordance with these installation instructions and the Gas Safety (Installation and use) Regulations 1998. Failure to install appliances correctly could lead to prosecution. FIREPLACE / SURROUND SUITABILITY The fire is suitable for hearth mounting or wall mounting. It must not be fitted directly onto a carpet or other combustible material.

Miser System

It must not be fitted to combustible walls. This fire is suitable for the following hearth / surround types: Non-combustible hearths / surrounds. Brick / stone built chimneys and any chimney or flue which has been used for an appliance burning fuel other than gas must be thoroughly swept. The base of the chimney/flue must also be thoroughly cleared of debris etc. Any under floor air supply to the fireplace must be completely sealed off. Ensure that the inside of the chimney/flue is in good condition along its length and check that there is no leakage of smoke through the structure of the chimney during and after the smoke pellet test. The front opening of the fireplace must be between 305mm and 440mm wide, and between 580mm and 650mm high.

If the opening is larger than this, then a surround must be constructed in a suitable non-com bustible material to create an opening to these limits. Allow a minimum flat surface of 10mm around the opening to ensure that the closure plate can be sealed to the fireplace. This appliance has been tested for use in a pre-cast flue block complying with BS EN 1858. In accordance with BS EN 1858, pre-cast flues built with directly plastered faces (front or rear) are not correctly installed as to ensure proper operation with any type of gas fire. PACKING CHECK LIST 1 off Firebox / Burner Assembly 1 off Flue Spigot 1 off Closure Plate 1 off Literature / Loose Items Pack 1 off Pack of Screws & Fixings for Wall Mounting 4 off Ceramic Radiants – Packed inside firebox 1 off AA Battery 1 off Arthritic control knob and 2 off self adhesive pads INSTALLATION OF FIRE. 3 To Remove the Lower Outer Case Fixing Screws Fig. 4 Remove the Upper Outer Case Fixing Screws Remove the flue spigot restrictor if the fire if the fire is the to be fitted to a pre cast flue.

The flue spigot restrictor is attached to the fire back with two screws. CLOSURE PLATE.

Fit the closure plate to the fireplace opening and ensure that it has a flat sealing area of at least 10mm sealed on all sides. 5 below Dimensions stated are for closure plate supplied Fireplace Opening 460mm Fig. WALL MOUNTING.

(NON COMBUSTIBLE WALLS ONLY) NOTE: When the fire is wall mounted, the base of the fire must be a least 150mm above the floor level. Remove the feet from the base of the fire. (4 screws in each.) Mark the position of the upper fixing holes on the wall with reference to fig.

GAS TIGHTNESS Remove the pressure test point screw from the inlet elbow and fit a manometer. Turn on the main gas supply and light the fire as described in section 2.7 and carry out a gas tightness test.

Check that the gas pressure is 20.0 mbar (± 1.0 mbar), 8.0 in w.g. +/- 0.4 in w.g. LIGHTING THE APPLIANCE AN ARTHRITIC CONTROL KNOB IS SUPPLIED FOR USE WITH THIS PRODUCT IF REQUIRED, SEE SECTION 4.6 FOR FITTING INSTRUCTIONS. Light the pilot by depressing the control knob at the “off” position and turn anti-clockwise (with the control depressed) to the second position marked. Replacement of parts must be carried out by a competent person such as a GAS SAFE registered gas installer. The part numbers of the replaceable parts are as follows, these are available from your local Flavel stockist, whose details can be found on the BFM Europe website, address on the back page. MAINTENANCE INSTRUCTIONS Servicing Notes Servicing should be carried out annually by a competent person such as a GAS SAFE registered engineer.

The service should include visually checking the chimney and fire opening for accumulations of debris and a smoke test to check for positive up-draught in the chimney. 10 Removing the Upper Outer Case Fixing Screws REMOVING THE BURNER ASSEMBLY FROM THE FIRE Remove the outer case as section 3.1 Unscrew the pilot from the pilot bracket attached to the burner. See section 3.3 Unscrew injector fixing bracket. 11 Unscrew four burner fixing screws.

12 Burner removal Position of Burner Screws REMOVING THE CONTROL TAP / MICROSWITCH FROM THE FIRE Remove the outer case as section 3.1 Remove the service plate from the control valve air duct by unscrewing the two screws. 13 Unscrew the control valve lock-nut from the top of the control valve. 14 Control Valve Panel Removal Remove 2 off Screws as Indicated To refit the control valve, reassemble in reverse order noting that the control tap locates with a flat in the control fixing panel. Carry out a gas soundness test after re-assembly. REMOVING THE ODS- PILOT ASSEMBLY Note: Because this appliance is fitted with an atmosphere sensing ODS-pilot it is not possible to replace the thermocouple separately, because the. 15 REPLACING THE RADIANTS When replacing the radiants, always ensure that they are correctly located as shown in Fig. 16 Ensure that the rear face of the ceramic radiant is touching the front edge of the position- ing plate as indicated Front edge of the Positioning Plate.

SECTION 4 - USER INSTRUCTIONS 4.1 CONDITIONS OF INSTALLATION It is the law that all gas appliances are installed only by a competent (e.g. GAS SAFE Registered) Installer, in G.B. In accordance with the installation instructions and the Gas Safety (Installation and Use) Regulations 1998. Failure to install appliances correctly could lead to prosecution.

ABOUT YOUR NEW FLAVEL MISERMATIC GAS FIRE The Flavel Misermatic gas fire incorporates a unique and highly developed heat exchanger which combined with the radiant plaques gives maximum heat whilst maintaining reasonable running costs Please take the time to fully read these instructions as you will then be able to obtain the most effective and safe operation of your fire. OPERATING THE FIRE AN ARTHRITIC CONTROL KNOB IS SUPPLIED FOR USE WITH THIS PRODUCT IF REQUIRED, SEE SECTION 4.6 FOR FITTING INSTRUCTIONS. Light the pilot by depressing the control knob at the “off” position and turn anti-clockwise (with the control depressed) to the second position marked.

4.4.2 CLEANING THE RADIANTS The ceramics may discolour slightly over a period of time, this is normal for radiant fires. Any dust or small soot deposits that accumulate on the ceramics can easily be cleaned. Carefully remove the ceramics and brush gently with a soft brush. To remove the ceramic, remove the dress-guard as shown in fig.

REPLACING THE BATTERY IN THE IGNITION GENERATOR The battery holder is located at the bottom R/H/S of the fire, unscrew the cap, fit a new AA battery and re-fit the cap. 4 Battery Cap Spark Generator AA Battery IN THE EVENT OF THE FIRE FAILING TO LIGHT, PLEASE VISUALLY CHECK FOR SPARKING AT THE IGNITION ELECTRODE ON THE PILOT. FITTING THE ARTHRITIC CONTROL KNOB The arthritic control knob is supplied in the loose items pack, this item should be used if necessary as an aid to operate the control valve on the fire. To fit the arthritic control knob firstly fit the self adhesive pads to the arthritic control knob itself as shown below in Fig. Finally, re-fit the arthritic control knob assembly to the product as shown overpage Re-fit the control knob assembly to the fire as shown below in Fig. 7 Ensure that the indentation in the arthritic control knob is positioned as shown below in Fig.

GAS SAFE registered gas installer. The part numbers of the user replaceable parts are as follows, these are available from your local Flavel stockist whose details will be found on the BFM Europe website, address shown below Ceramic Radiant Plaques B-48680 Part No.